Smart lift management for modern lift companies

Remote lift monitoring for independent service providers.Cut unnecessary call-outs by up to 30% and prove your value with transparent lift data. Read moreBook a demo

Real-time lift monitoring gives instant insights to detect issues before disruptions.

Proactive maintenance minimizes downtime by preventing failures in advance.

Compatible with all lift systems, Orion works independently of manufacturers.

Maximum security ensures no connection to lift controls, eliminating cyber risks.

Lift service is changing

– are you keeping up?

In a rapidly evolving industry, service providers need smarter, more efficient ways to manage lifts. SafeLine Orion is an independent, brand-agnostic monitoring solution that works with all lift brands, giving service companies the flexibility and control they need to optimize operations.

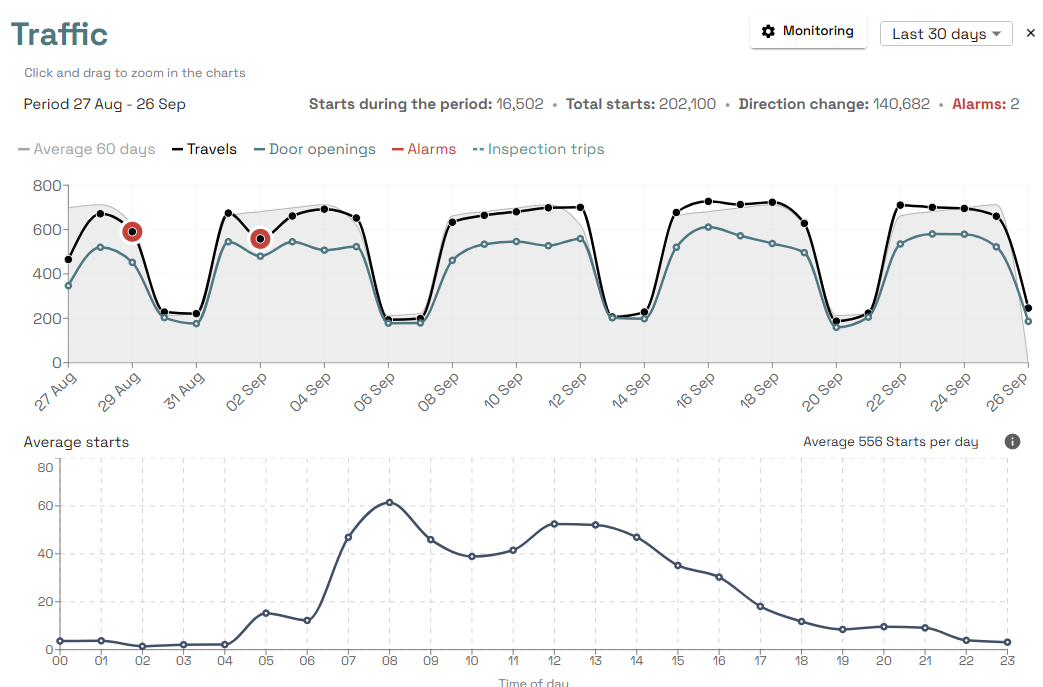

With real-time monitoring and predictive analytics, Orion helps reduce unnecessary service visits, lower costs, and improve resource allocation. By offering transparent data and proactive maintenance, service providers can build stronger customer relationships and secure long-term contracts.

Discover how SafeLine Orion transforms hospital lift management with advanced technology

Watch this video to see how our platform ensures uninterrupted vertical mobility, enhances patient and staff safety, and delivers real-time insights for facility managers and service providers — helping hospitals maintain critical operations around the clock.

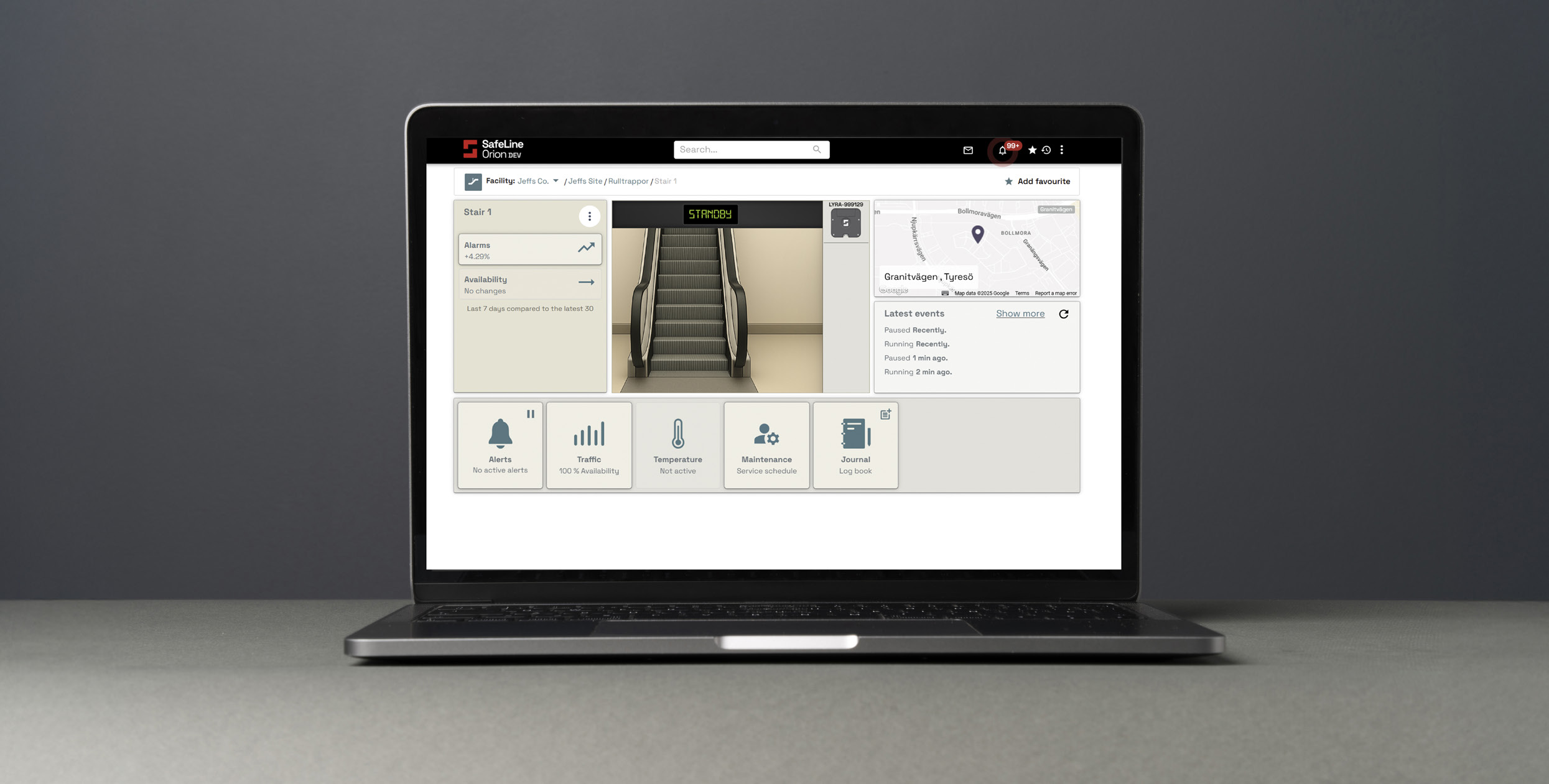

Smart lift management in the cloud with SafeLine Orion

Helps you to access your whole lift portofolio – All your lift data in Real time

Always-on connectivity with SafeLine SIM cards

Reliable connectivity is the foundation of remote lift monitoring. SafeLine’s fully managed, multi-network SIMs keep your emergency lines and Orion-connected devices online – even in challenging building environments. Gain real-time visibility in the SIM management portal while our SIM team handles subscriptions, refills, and alerts, so your lifts stay connected and compliant.

Why lift companies choose SafeLine SIM Cards:

-

Automatic connection to the strongest available network

-

Full SIM and usage overview in a dedicated portal

-

Optimised for lift environments and technical rooms

-

Managed subscriptions, refills, and alerts by the SafeLine SIM team

-

Designed to support Orion and other SafeLine devices

The Shift: From Reactive to Predictive

Many lift service companies still operate on fixed maintenance schedules, sending technicians for routine checks rather than focusing on real issues. This approach leads to:

What is driving change?

- Unnecessary service trips, increasing operational costs

costs and technician workload. - Missed early warning signs, resulting in costly emergency callouts.

- Limited customer trust, as property owners demand more visibility into lift performance.

- Without real-time data, lift companies are forced to operate reactively, making it harder to optimize resources and provide cost-efficient, high-value service.

With SafeLine Orion, lift companies gain the tools to work smarter – shifting from fixed maintenance cycles to data-driven decision-making.

The Solution: Smarter, Data-Driven Lift Service

Our cloud platform, SafeLine Orion is designed to support lift service providers and serve as a trusted partner. By providing real-time monitoring, predictive insights, and full data access, Orion enables more efficient and flexible service planning.

How SafeLine Orion helps lift companies:

- Monitor lift performance in real-time and detect issues before they cause downtime.

- Optimize maintenance schedules based on actual lift usage, not just fixed intervals.

- Reduce emergency callouts by preventing failures before they happen.

- Improve efficiency – technicians focus on the lifts that actually need attention.

- Strengthen customer relationships – provide transparency and better service.

Case Study

Smarter Lift Service with SafeLine Monitoring service

By implementing SafeLine Orion, the company transitioned from scheduled maintenance to a needs-based approach. With real-time data and predictive insights, they reduced unnecessary service visits, improved response times, and increased overall lift uptime.

The result: smarter operations, fewer disruptions, and more satisfied customers.

Reduced unnecessary service visits

%

Reduction in emergency callouts

%

People using lifts per month

Installation year

Download whitepaper

Discover how lift companies can improve efficiency, reduce unnecessary service trips, and offer more valuable, data-driven contracts. This white paper shows how SafeLine Orion enables service providers to stay competitive and deliver smarter, more transparent lift management.

Key features of SafeLine Orion

1

Take full control of your lifts – and your uptime

Your lifts are a crucial part of your building’s infrastructure, but unexpected failures and maintenance costs can quickly add up. SafeLine Orion gives you real-time visibility over every lift in your portfolio, helping you reduce unplanned downtime. Stay in control of your assets and make data-driven decisions that optimize operations.

- Enable proactive work to reduce unplanned downtime and service call-outs.

- Extend the lifespan of your lifts through predictive maintenance.

- Reduce tenant complaints by ensuring reliable service.

2

Smarter maintenance, Better service.

Most lift maintenance today remains reactive—you respond only when something stops working. SafeLine Orion helps lift companies shift to a more proactive service model by providing predictive insights into lift performance, enabling you to plan interventions before issues affect the end user.

Instead of fixed routines and unnecessary visits, you get a clearer picture of what each lift actually needs—making maintenance more timely, more targeted, and more aligned with customer expectations.

- Move from routine visits to needs-based service with data-driven insights.

- Plan maintenance with confidence using predictive signals and lift health trends.

- Reduce disruptions and improve the end-customer experience through proactive interventions.

3

Your lifts. Your data. Your decisions.

Unlike many other lift monitoring systems, SafeLine Orion is completely independent. That means you get full control over your own lift data, instead of relying on a single supplier’s reports. Choose the service providers that work best for you, without being locked into a restrictive contract.

- Keep full ownership of your operational data.

- Work with any lift service provider – no manufacturer lock-ins.

- Gain unbiased, transparent insights to make better decisions.

4

Maximum security – no risk of cyber threats.

Cybersecurity is critical in modern buildings, and SafeLine Orion is designed with complete data protection in mind. Unlike other systems, Orion does not connect to the lift’s core control system, ensuring there’s no risk of hacking or operational interference. Your data remains safe, and your lifts remain secure.

Elevate magazine is here!

Stay updated with the latest innovations and insights from SafeLine. In this issue, we celebrate 30 years of lift safety, explore the future of digitalisation and sustainability, and showcase smart solutions like SafeLine Orion, Lyra, and VoIP technology. Download the magazine and discover how we’re shaping the future of lift management together.

Fill in the form to download the magazine

Resources

Resources

Introduction

Let’s get started!

See what SafeLine Orion can do for your lift company

Book a short demo with our team and see how real-time lift monitoring can reduce unnecessary call-outs, improve planning for your technicians, and give you full control of your lift portfolio.

- Walk through key features and real use cases for lift companies.

- See how Orion connects to your existing lifts and mixed-brand portfolio.

- Get clear answers to your technical and operational questions.

It’s free and non-binding to book an introduction – and in one session you’ll get a complete overview of the platform and the pricing options that fit your portfolio size and needs.

FAQ

Why do we lack transparency in lift condition and service delivery?

Short answer: Because lift data and service documentation are often fragmented across suppliers, sites, and formats—making it hard to verify what’s happening and why.

Details:

-

Information lives in emails, PDFs, service portals, and site logs.

-

Mixed fleets (different brands/ages) make consistent visibility harder.

-

Outcomes become hard to benchmark across buildings.

What does “portfolio control” mean in practice?

Short answer: Portfolio control means you can view lift performance and issues consistently across buildings, not one site at a time.

Details:

-

One reporting structure across the whole estate

-

Easier prioritization (critical buildings, recurring issues, worst performers)

-

Fewer “blind spots” when staffing changes or suppliers rotate

How do we get a “single source of truth” across multiple buildings?

Short answer: Standardise how lift events, actions, and outcomes are captured so reporting is consistent and comparable across the portfolio.

Details:

-

Use one common reporting model for all sites

-

Ensure every action has: what/when/why/result

-

Keep owner-accessible records independent of any single supplier portal

Why do maintenance costs keep rising and still feel unpredictable?

Short answer: Costs become unpredictable when issues are detected late, repairs are reactive, and evidence is insufficient to prevent repeat callouts.

Details:

-

Breakdowns create premium (urgent) work and disruption costs

-

Root causes can be missed when documentation is inconsistent

-

Hard to forecast when you can’t see trends portfolio-wide

How do we reduce unplanned repairs without increasing risk?

Short answer: Move from “react after failure” to “act on early signals” with prioritized interventions and verified outcomes.

Details:

-

Identify recurring fault patterns (by building/lift type)

-

Prioritize actions by criticality (hospital vs office vs residential)

-

Track whether a fix actually reduced incidents

How do we reduce unnecessary maintenance visits?

Short answer: Base visits on need and evidence—so the right work happens at the right time, with fewer wasted callouts.

Details:

-

Use consistent triggers for “send a technician.”

-

Validate outcomes: what changed after the visit?

-

Reduce repeat visits by documenting the root cause and resolution

What’s the fastest way to reduce downtime across the estate?

Short answer: Improve early detection, triage faster, and prioritize fixes using consistent portfolio visibility.

Details:

-

Downtime reduction is usually a process problem, not only a technical one

-

“Same day visibility” beats “end-of-month reporting.”

-

Benchmark worst performers and address systemic causes

How do we prioritize actions when multiple lifts have issues?

Short answer: Rank issues by safety/criticality, building impact, and recurrence—then allocate service capacity accordingly.

Details:

-

Critical buildings first (healthcare, mobility access, public sites)

-

Repeat incidents next (high recurrence = high cost)

-

Then optimize the “long tail” of low-frequency issues

How do we reduce tenant complaints related to lifts?

Short answer: Reduce recurring faults and improve response predictability—then communicate transparently when issues occur.

Details:

-

Track complaint drivers (type, building, time)

-

Reduce repeat callouts (same issue returning)

-

Provide consistent status updates internally so front-line teams can respond

Why is compliance harder with multiple buildings?

Short answer: Because evidence is scattered and practices vary between sites and suppliers, making it difficult to demonstrate control consistently.

Details:

-

Different service providers = different documentation styles

-

Local “workarounds” emerge over time

-

Audit readiness becomes manual and fragile

What compliance reporting should we be able to produce quickly?

Short answer: You should be able to show what was done, when, why, and with what outcome—per lift and across the portfolio.

Details:

-

Service/incident history per asset

-

Proof of corrective actions and follow-up

-

Trends and risk areas across buildings

How do we reduce compliance work that’s currently manual?

Short answer: Standardize documentation and reporting so evidence is created as part of operations—not retrofitted before audits.

Details:

-

Define mandatory fields for every action/event

-

Ensure ownership: who signs off and who stores evidence

-

Use consistent naming and categorization across the estate

What do boards/management usually want to know about lifts?

Short answer: They want evidence of risk control, downtime trends, cost drivers, and whether suppliers are delivering measurable improvement.

Details:

-

Portfolio KPIs (downtime, incidents, repeat callouts)

-

Cost predictability (planned vs unplanned)

-

Risk hotspots (buildings, lift types, recurring issues)

How do we stop living in spreadsheets and email threads?

Short answer: Create a repeatable reporting system that captures events and outcomes consistently and exports portfolio-ready views.

Details:

-

Agree on one taxonomy (fault types, priorities, outcomes)

-

Require documentation completeness (no “closed” without result)

-

Make reporting a routine, not a monthly scramble

Can we benchmark performance across buildings and suppliers?

Short answer: Yes—if metrics are consistent and data access is independent, benchmarking becomes objective instead of anecdotal.

Details:

-

Standardize KPIs and definitions

-

Compare “repeat incidents per lift” and “time to restore service”

-

Use trend lines, not single incidents

What is “manufacturer lock-in” in lift operations?

Short answer: Lock-in happens when data access, tooling, and processes depend on one manufacturer ecosystem, limiting your freedom to change suppliers or standardize reporting.

Details:

-

Switching costs become operational, not just contractual

-

Mixed fleets become harder to manage consistently

-

Innovation depends on one vendor's roadmap

How do we avoid lock-in while keeping a good supplier relationship?

Short answer:

Keep relationships collaborative, but ensure your organization retains independent visibility, consistent reporting, and decision control.

Details:

-

Independence reduces conflict—because decisions rely on evidence

-

Suppliers can still deliver; you just verify outcomes consistently

-

Helps long-term trust through shared facts

What does “open protocol” mean for a property owner?

Short answer: Open protocol typically means better interoperability and fewer dead-ends when integrating with your building systems or changing vendors.

Details:

-

Easier integration into broader property tech stacks

-

Less dependence on proprietary portals

-

More flexibility as your portfolio evolves

What cybersecurity questions should IT ask before connecting lift assets?

Short answer: Ask how data is protected, who has access, what’s integrated, and how risks are controlled and documented.

Details:

-

Encryption and secure authentication

-

Role-based access and audit logs

-

Clear data ownership and retention policy

-

Security documentation for internal risk assessment

Who owns the operational lift data?

Short answer: For portfolio governance, property owners should retain access and control over operational data so decisions and reporting remain independent.

Details:

-

Enables benchmarking and supplier accountability

-

Reduces switching friction

-

Supports consistent governance across sites

How should we think about GDPR/NIS2 in this context?

Short answer: Treat connected lift data as governed operational data: define lawful basis (if personal data exists), minimize exposure, and document security controls and responsibilities.

Details:

-

Data minimization and purpose limitation

-

Clear processor/controller roles (where applicable)

-

Internal security review and documentation

(This is governance guidance, not legal advice.)

How do we roll out across 24+ lifts without disrupting operations?

Short answer: Start with a representative pilot, establish baseline KPIs, then scale building-by-building with a standard installation and reporting playbook.

Details:

-

Pilot mix: different brands/ages/traffic profiles

-

Baseline first: downtime, incident rate, repeat callouts

-

Scale after measurable improvement and stakeholder buy-in

What’s the difference between non-invasive and invasive installation models?

Short answer: Non-invasive approaches aim to minimize disruption and changes to core systems, while invasive approaches may enable deeper integration but require more planning and approvals.

Details:

-

Choose based on risk appetite, lift type, and governance requirements

-

Document change management and safety considerations

-

Align with compliance and supplier agreements

How do we get buy-in across Operations, Procurement, Technical/Compliance, and IT?

Short answer: Tie the rollout to each stakeholder’s measurable outcomes: fewer disruptions (Ops), clearer supplier accountability (Procurement), audit readiness (Compliance), and controlled risk (IT).

Details:

-

Use shared KPIs across stakeholders

-

Agree on definitions (what counts as “downtime”)

-

Publish a simple governance model (who decides what)

Why should we consider SafeLine to solve our key lift-portfolio challenges—lack of service transparency, rising unplanned costs, compliance complexity, and vendor lock-in?

Short answer: SafeLine is positioned to help property owners improve transparency, reduce disruptions, and maintain flexibility through faster deployment options and interoperability (e.g., open protocol), without forcing a single-vendor operating model.

Details:

-

Emphasis on practical rollout (short installation time)

-

Flexibility options (non-invasive vs invasive models)

-

Focus on interoperability and long-term control

Can we benchmark performance across buildings and suppliers?

Short answer: Yes—if metrics are consistent and data access is independent, benchmarking becomes objective instead of anecdotal.

Details:

-

Standardize KPIs and definitions

-

Compare “repeat incidents per lift” and “time to restore service”

-

Use trend lines, not single incidents